LED streetlights play a crucial role in urban lighting. However, these lights face specific issues due to their environment and long-term use. This article will explore common LED street lights problems and solutions.

Common LED Street Lights Problems

1. LED Driver Failure

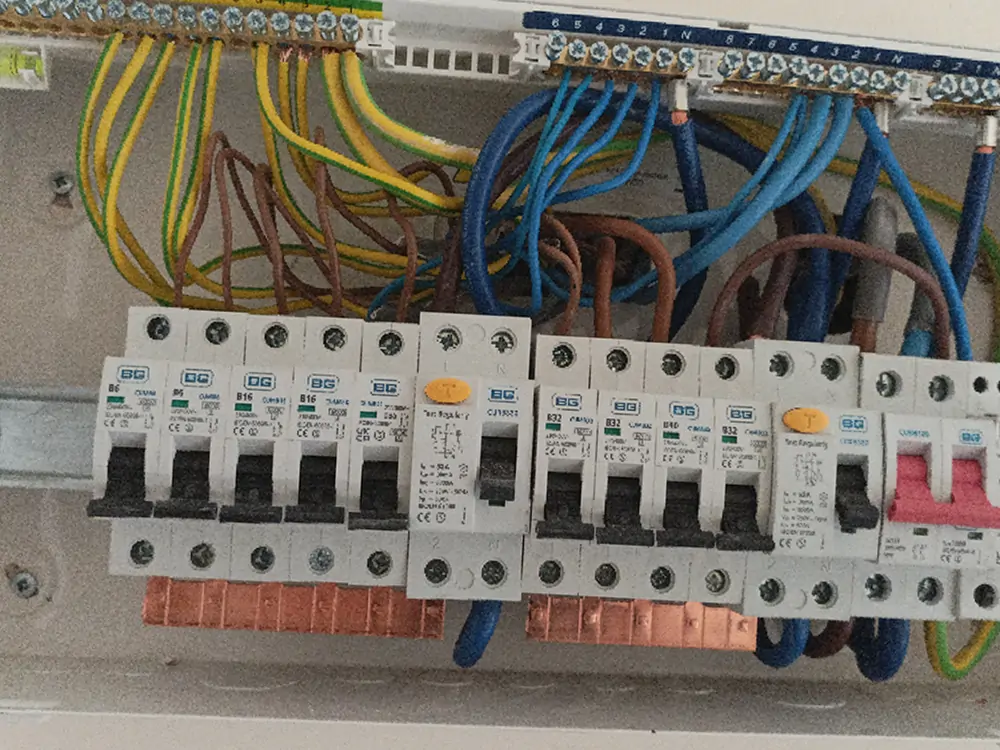

The LED driver is a vital part of LED street lighting. Its primary function is to power the LEDs. A faulty LED driver can cause partial LED failure or flickering. Choosing street lights from trusted LED driver manufacturers reduces the need for replacements, ensuring stable and reliable performance over time.

A Nexus of Power and Control: The LED Driver

The LED driver is the central component of every LED street light. It controls electrical power and light generation. This ensures the LEDs get the exact power they need. This results in bright, efficient lighting. But, like any technology, the LED driver is imperfect. It can face errors, malfunctions, and wear over time.

Unsettling Domino Effect

An LED driver failure triggers a chain reaction throughout the luminaire. This can lead to complete light failure but frustrating failures, like flickering LEDs. These LEDs emit erratic light patterns, which may irritate pedestrians. Even a tiny malfunction can affect the city’s aesthetics. Often, it’s a partial LED failure.

Directing the Solution: A Symphony of Quality

The selection of an LED driver is crucial in this changing environment. Investing in street lights with reputable LED driver brands builds trust.

2. Poor LED Chips

High-quality LED circuits are essential for durable and efficient street lights. LED chips with gold conductors are preferred, as they have better electrical and thermal conductivity and corrosion resistance.

Lower-grade LED circuits with other conductors are more likely to fail. Over time, this affects the light’s performance and lifespan.

For example, buy high-quality LED chips from trusted manufacturers. These chips offer a wide luminous angle, low power, and high light efficiency.

3. Issue in SPD Function

SPDs protect electronic devices, like LED streetlights, from damage caused by surges. These surges can happen due to external street lamp interference. Although LED drivers may have built-in SPDs, extra protection is needed. Moreover, SPDs should be installed for unstable power or intense lightning.

4. Unreasonable Heat Dissipation

Every 10°C increase in the junction temperature of the LED chip reduces its service life. This is a critical factor in the performance of LED devices. As the temperature rises, the semiconductor components degrade faster.

LED street lanterns need high luminosity and operate under harsh conditions. Efficient heat dispersal is essential for their longevity. If heat dissipation is not addressed, LEDs will speed up degradation and diminish stability.

5. Lower IP/IK

The IP and IK ratings are vital for outdoor LED street lighting. Low IP ratings allow water to seep into electrical components. It causing damage and potential electric discharge hazard. Light with low IK ratings is more prone to damage, which poses a safety risk to pedestrians.

6. Poor Powder Coating

High-quality particle coatings street light shielding outdoor street lights from corrosion. It also prevents from abrasion, and chemical damage. It improves their performance and longevity in harsh conditions.

Street lights should be bought with salt spray test reports. These reports confirm their durability and resistance to factors like salt and moisture.

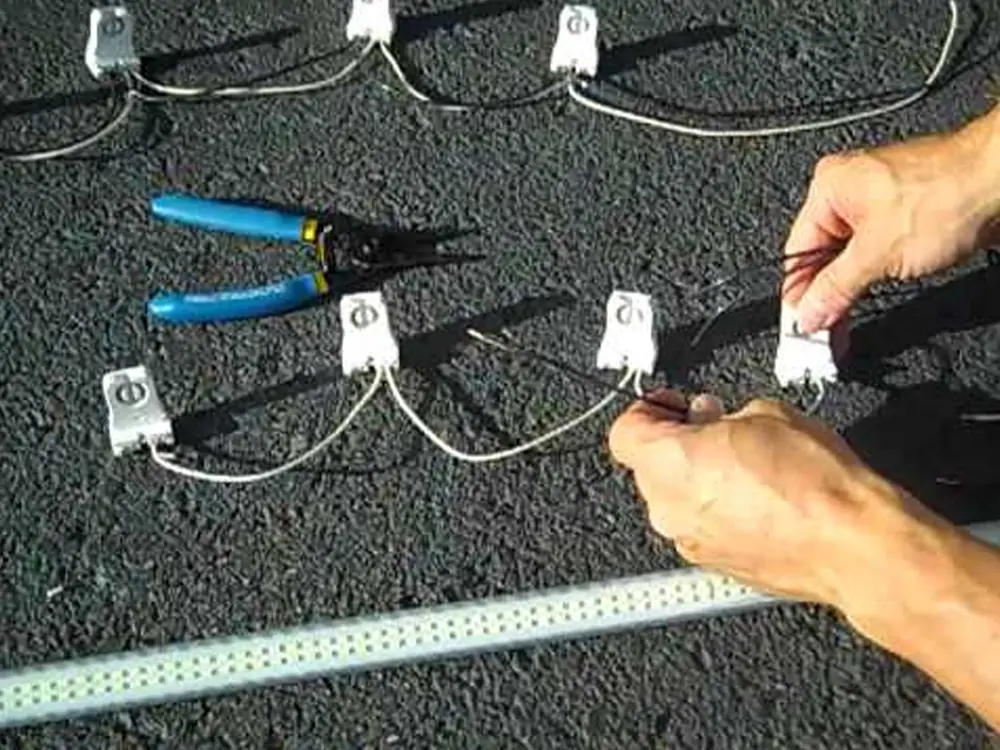

7. Substituting Copper Wires for Gold Wires in LEDs

Many LED manufacturers substitute inferior products for superior ones. Gold wires in LEDs are more stable than copper alloy wires. Silver alloy wires are less stable than gold wires. This stability is essential for LED performance and longevity. Gold’s resistance to corrosion ensures a longer lifespan. Other materials like copper and silver degrade faster, reducing efficiency over time. Gold maintains its properties, ensuring reliable LED function.

These alternative wires are much less stable. Silver alloy wires and gold-coated silver alloy wires are prone to corrosion. They are vulnerable to sulfur, chlorine, and bromine. Copper wire is also at risk of oxidation and vulcanization.

When these materials are used in LEDs, they become more vulnerable to chemical damage. This reduces the reliability of the light sources. Over time, the wires can break, causing LED beads to fail.

8. Lighting Distribution Issue

The distribution of light from LED streetlights depends on the optics lenses. Choosing street lighting with good light distribution helps save energy. It also ensures even illumination along the roadway. This prevents LED street lights problems like excessive brightness or dark spots. Proper distribution reduces light pollution in urban areas. It creates a safer, more balanced environment for everyone.

9. Insufficient Efficiency

LED streetlights’ efficiency depends on the quality of their circuits. The performance of optical components also plays a crucial role. Drivers are another critical factor influencing efficiency. Manufacturers must provide accurate lumen efficacy data for their products. This helps in assessing the actual performance of the lights.

Overstated figures may lead to underperforming lighting solutions. It’s essential to ensure that the lighting solutions meet quality standards. Transparency in these specifications ensures reliability and excellent street light effects.

Letzte Worte

High-quality LED street lighting is crucial for efficient road construction and ensures safety in urban areas. Proper lighting makes cities safer for residents, and well-lit streets improve visibility for drivers and pedestrians.

Investing in quality lighting improves urban development. Efficient lighting systems contribute to energy savings and sustainability. Investing in reputable manufacturers builds long-term urban development. Collaboration with trusted partners leads to efficient project execution.